Balancing working wheels in centrifugal pumps plays a key role in ensuring their reliable and efficient operation. The goal consists of minimizing dynamic loads and causing imbalanced masses, which reduces vibrations and prolongs the life of pump components. More about pumps mechanical repair Dubai.

Science Dynamics: How Works Balancing

Balancing based on advanced principles dynamics and kinematics. Imbalance occurs when masses from working construction are unevenly distributed around axis rotation. This leads to the occurrence of centrifugal force — key factor vibrations. Solution — Adjusting mass wheels, reducing or eliminating these forces.

- Analyzes centrifugal forces acting on the wheel.

- Takes into account mass, shape, and speed.

- Result is even distribution mass.

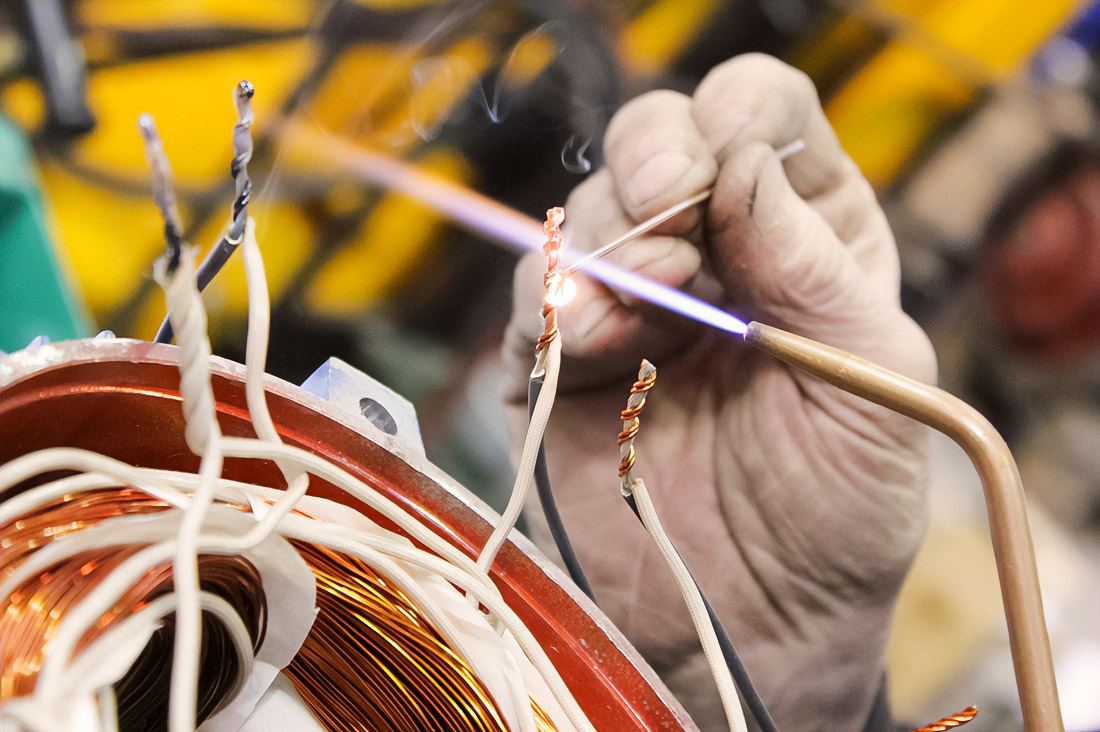

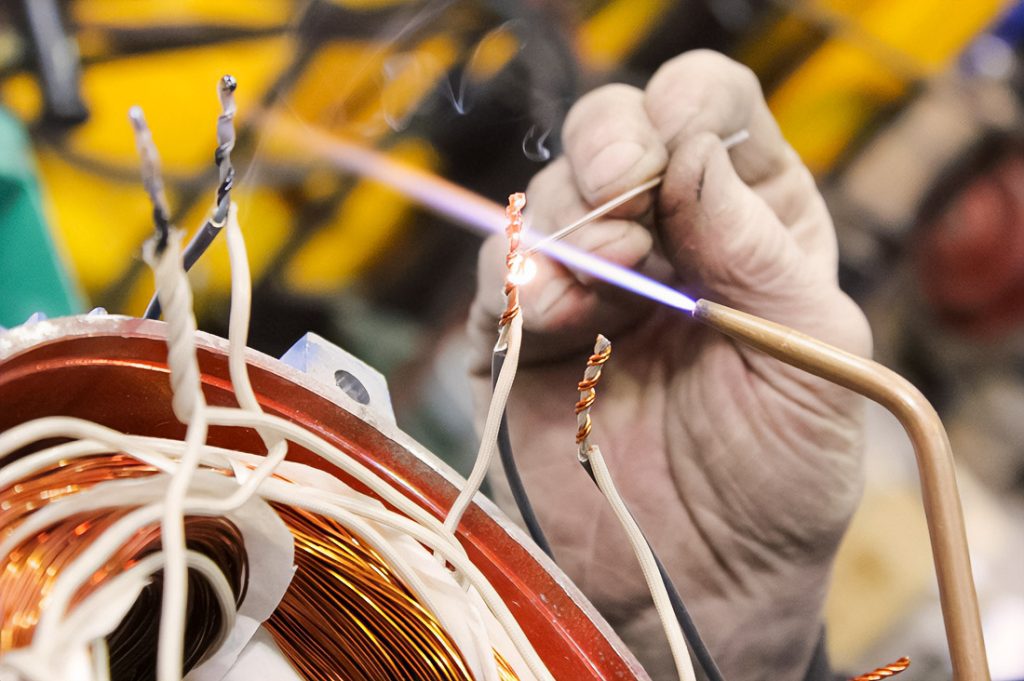

Innovative Methods Balancing: Technological Breakthroughs

Modern technologies open several methods of balancing, each with its unique advantages and limitations.

- Static balancing: Applicable for simple constructions, eliminates imbalance in one plane, using balancing machines.

- Dynamic balancing: Ideal for complex wheels, it takes into account imbalance in several planes with the use of high-precision equipment.

- Computer balancing: Allows to simulate and analyze distribution mass with the help of modern technologies and computers.

Negative Consequences Imbalance: What Influence It Exerts?

Imbalance working wheels can bring many problems, threatening the efficiency and reliability of centrifugal pumps. Learn more about influence vibrations on vibrations.

- Vibrations: Their amplification increases the load on equipment, causing accelerated wear.

- Wear bearings: Can cause uneven loads and premature failures.

- Decrease efficiency: Leads to high energy consumption and reduced performance indicators.

Advantages Superior Balancing: Why This Important?

Precise balancing working wheels provides numerous advantages, vitally important for maintaining operability pumps. Learn more about importance balancing through physical balance.

- Increase reliability: Reduction vibrational loads prolongs life equipment.

- Decrease costs on maintenance: Less often necessary replacement worn parts.

- Improve performance: Energy efficiency and increased performance system.

Regular Monitoring and Balancing: Fundamentals Long-term Success

To maintain centrifugal pumps in the best condition, follow a series of important recommendations.

- Constant inspections vibrations with the help of modern equipment.

- Inclusion balancing in regularly scheduled activities.

- Use precise equipment for balancing procedures.

- Training personnel modern methods and technologies.

Real Examples: Inspiring Success Stories

Let’s consider examples that highlight the importance of quality balancing.

- At one industrial facility, after dynamic balancing, decreased vibrations by 60%, prolonging life bearings and reducing costs on repairs.

- Oil refinery was able to reduce energy consumption pumps by 15%, which significantly saved funds and increased production indicators.

These examples demonstrate the significance and necessity of balancing as integral part of successful management systems pumps, guaranteeing reliability and long-term efficiency equipment.

Basketball fan, mother of 2, fender owner, vintage furniture lover and HTML & CSS lover. Performing at the fulcrum of modernism and programing to give life to your brand. I sometimes make random things with friends.