Generator Repair and service can be a costly affair. Here are a few things to keep in mind when you need to repair your generator. If you are considering this type of repair, it is important to have your generator serviced by a professional. In addition to this, you should also know about generator preventative maintenance. If you want to avoid costly repairs, consider rewinding your generator.

Service By a Mechanic

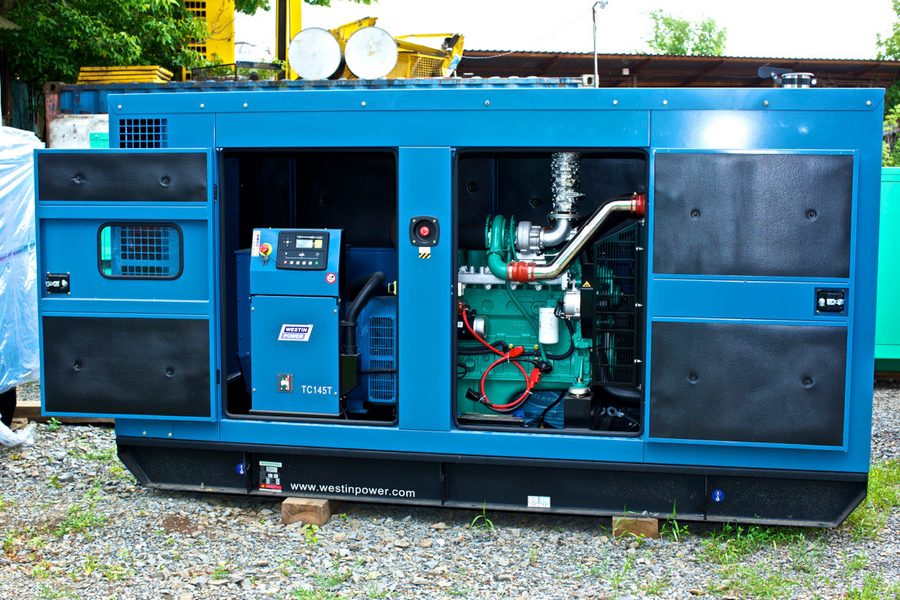

Generator mechanics are responsible for the routine maintenance and repair of generators. They should diagnose the cause of problems and come up with a solution to fix it. They also handle purchasing spare parts and control panels. Additionally, they will install or repair switchgear. These mechanics must be skilled and trained in a variety of technologies.

Cost of Repairs

If you own a backup generator, it’s important to keep it properly maintained. The best way to do this is to check the oil and coolant levels at least once a week. Regular inspections and maintenance can prevent major breakdowns and costly repairs. It’s also important to keep the unit running for at least 20 minutes a week if possible. Regular maintenance can also help detect small problems that could cost you money in the future.

Preventative Maintenance

A proactive approach to generator repair is critical. Proper preventative maintenance prevents costly outages before they occur. This approach is often less expensive than emergency repair. Generators are susceptible to wear and tear and may require new fuel filters or oil. It may also be time to replace corroded wires.

To prevent costly service trips, keep your backup power system in good condition with a customized scheduled maintenance plan. This will ensure that your backup power system remains in top condition and is compliant with its warranty. Experienced technicians will change filters, oil, and coolant. They will also inspect the components in the air intake system, such as the turbocharger. They’ll also look for loose connections, which may prevent the generator from starting properly.

In addition to preventive maintenance, generators must be cleaned to prevent carbon monoxide. This gas can be fatal if breathed in. A technician will position the generator outdoors, where fumes can dissipate. Proper cleaning and maintenance of the generator can also help protect the environment.

Rewinding a Generator

During maintenance, generators require rewinding. There are various methods to rewind a generator. It involves cleaning, changing spacers and clamping rings, and evaluating and replacing coils in the stator windings. Rewinding can also extend the useful life of the generator by improving the coil’s capacity.

The process involves stripping the generator’s windings with special tools and techniques. Before rewinding a generator, the insulation of the stator core is inspected to determine the torque and voltage. The new winding should not be installed in a core that is already too old. After the rewinding, the windings are evaluated again. This step is crucial to ensure the safety of the unit.

Changing the Air Filter

One of the most important parts of any generator is the air filter. It not only protects the engine from dirt, but also prevents larger particles from entering the combustion chamber. Those larger particles can cause premature wear to the materials inside the generator. If the air filter is not changed regularly, the engine can become inefficient and require more repair work.

To change the air filter, you must first turn off the generator. To do this, find the air filter assembly on the back of the generator. On some generators, the air filter is hidden by a side panel. Remove this panel using a screwdriver. If not you can look for professionals who provide AC motor rewinding and generator repairs.

Basketball fan, mother of 2, fender owner, vintage furniture lover and HTML & CSS lover. Performing at the fulcrum of modernism and programing to give life to your brand. I sometimes make random things with friends.